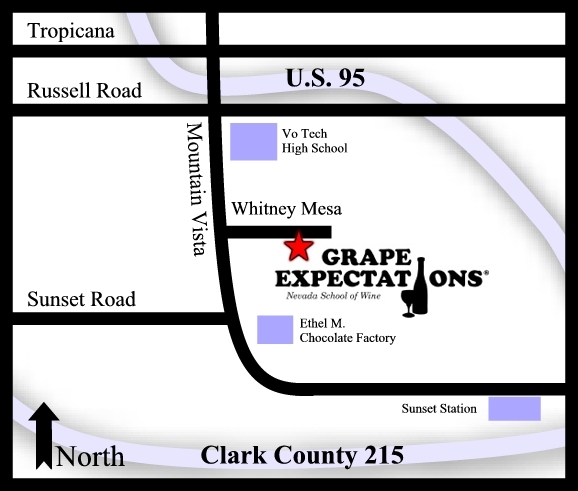

1971 Whitney Mesa, Henderson, NV 89014

Link to Day 2 Link to Review Journal Story

Link to bottling on Wednesday, June 17th

The verdict is in...at the winemaker's dinner on August 22, we got the Gold for Italian Wine!

Wine Making: Day 1 - Oct. 11, 2008

Videos

Day 1

--------------

--------------

--------------

--------------

Videos

Day 2

--------------

--------------

--------------

--------------

--------------

--------------

--------------

--------------

They weren't quite ready for us at 11:00, so they gave us

a bottle of wine and crackers to occupy our time.

Each barrel requires 21 boxes of grapes.

Each box weighs 36 pounds.

Gloria dumped one (almost)....

The whole grape and juice goes into a tub

This was checked and showed 14% alcohol content

Checking for acidity

Our tub is marked and we return in one week

The white wine in a stainless drum

Day 2 was actually one week after our Day 1 de-stemming

The Day 2 process consisted of pressing the grapes and

the next several months. The liquid will be tested perio

we stop by to check on the progress, our "work" is

At first look, you'd think all the juice had dried up.

Straining buckets were then pressed down

to get to the "easy" liquid.

The easy juice was pumped into an oak barrel

Then it was scooping the rest of the mash

into the presser.

The drum is finally filled

The oak barrel fills up. Any liquid left over is transferred to

the stainless steel drum you see behind the barrels. This

extra liquid will be used later to fill up the barrel during

the aging process.

What is left goes to a local pig farm

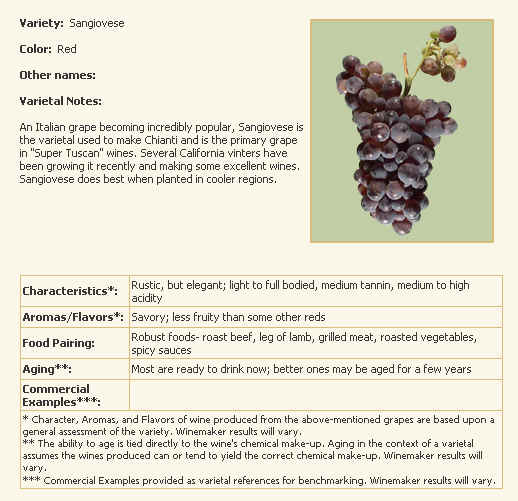

Grapes are brought in from Northern California wine country and refrigerated until the day before they are needed.

We are making Sangiovese, which requires 15 boxes of

Sangiovese grapes and 6 boxes of Chardonnay grapes

...I dumped the rest into the de-stemming machine

Most of the stems are separated

Yeast is added

This group was pressing grapes for white wine

process, adding yeast and letting the grapes ferment.

pumping it into the oak barrel, where they will stay during

dically and modifications will be made as needed. Unless

done for a while.

So the first step was to mix up the mash

The liquid starts to flow even without the pressing.

A base of wood is placed on the top

The pressing begins

When the pressing gets tough, you bring in the muscle.

Ready for the rack

P.S. - I now have a nice pair of purple tennis shoes!

Wine Making: Update - Jan 28, 2009

We stopped by for a tasting of our wine. At this point, the wine has been removed from the barrel,

the sediment removed, barrel cleaned and refilled. Additional tasting will be done over the next few

months and the bottling will be performed sometime in May or June. In their first year of operation

last year, Grape Expectations made 71 barrels. This year they are making 110 barrels.

-------------------------------------------------------------------------------------------------------------

April 2009 - Waiting for bottling day

The bottling process on Wednesday, June 17th

It took about 45 minutes to fill 250 bottles

Video 1 Video 2 Video 3 Video 4

The bottling crew Len, Rich, Gloria and Bill

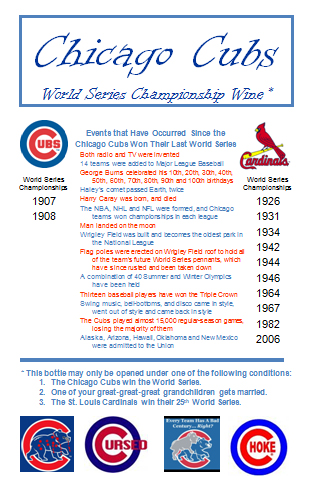

The label I made for my buddy Dan, a big Cubs fan